We install exposed aggregate for driveways, pathways and areas.

Exposed aggregate can be poured in a range of colours to suit your home and landscape, and creates a modern, beautiful area. Exposed aggregate as paths, patios and driveways adds a clean yet textured element in your landscape. We also install standard and coloured concrete, liquid limestone, and paving.

On this page:

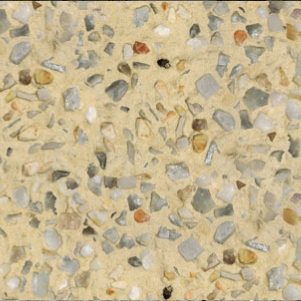

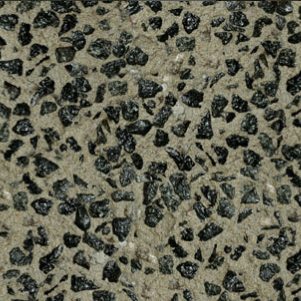

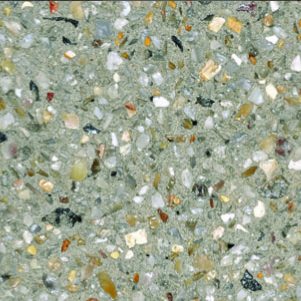

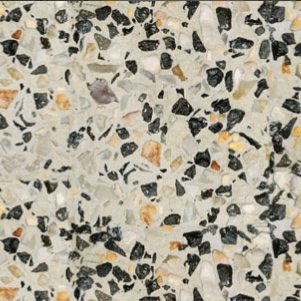

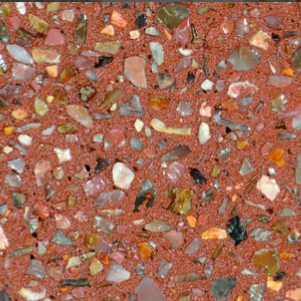

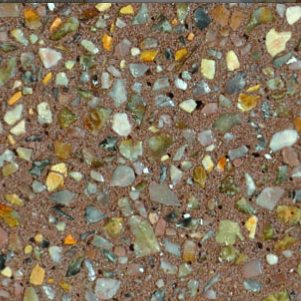

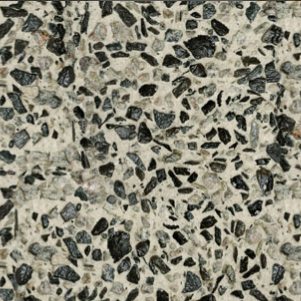

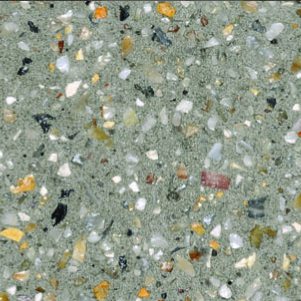

Exposed Aggregate Colour Range

See the colours available for exposed aggregate concrete

FAQs for Exposed Aggregate

Read some of our most frequently asked questions related to exposed aggregate concrete

Our Blogs on Exposed Aggregate Concrete

Find loads more information and pictures in our exposed aggregate related blogs

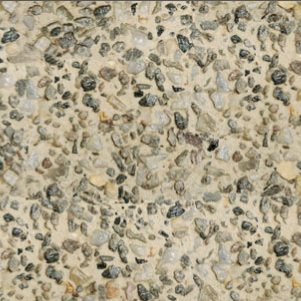

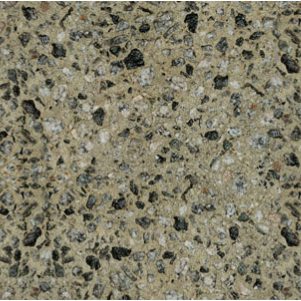

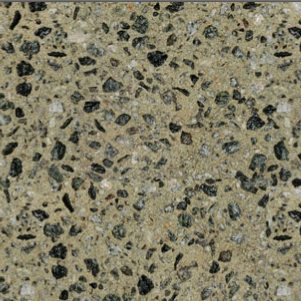

Exposed Aggregate Colours

Choose from a great range of exposed aggregate colours to personalise your space with beautiful natural stones.

*Availability of some colours may vary, and may be subject to change.

FAQs

FAQs

Find out answers to some of our most frequently asked questions for exposed aggregate.

Honed – Honing is achieved through grinding the top layer of the concrete to reveal a natural stone and a flat matt finish, perfect for alfresco, entertaining and pool areas where you want a smoother finish while maintaining the beauty of the exposed natural stone aggregates.

Polished – Achieved through grinding and polishing the concrete to create a highly glossy finish, perfect for any internal room of the home.

Exposed aggregate concrete provides all the benefits of standards concrete- hard wearing, durable, low maintenance, weather resistant and skid resistant, and the added appeal of the natural texture of the stone aggregates.

You will need to check with your local council for information on installing exposed aggregate for a council crossover (the continuation of your driveway onto your council verge to the road/ kerb.) Different councils have varied rules and regulations for crossovers, including what materials can be used. Click here to see our page on council crossovers, including a link to your local council website.

Control joints are placed in the concrete to encourage any cracking that may occur to happen in predetermined locations, allowing the customer to control to an extent where the cracking happens and reduce cracking as much as possible.

Control joints are planned at the design stage and placed at aesthetically appropriate areas where possible; spacing of the control joins in your concrete will be site and design specific.

You may choose a lighter exposure of the aggregate. You may also enquire as to the properties of the different aggregates used to determine if some provide a smoother finish. As the stones used in the concrete as aggregate are natural products, each possess unique and defining characteristics.

Additionally, you may choose to have the area honed, meaning you can maintain the appearance of the exposed stone aggregates while grinding the aggregates to a smooth finish that is more comfortable under foot- just be sure to seal your concrete around your pool area for safety, as well as protecting your concrete.

Exposed aggregate concrete surfaces, just like standard concrete, can become hot to walk on when temperatures soar if in an area that receives full sun.

Our Blog Posts

Our Blog Posts